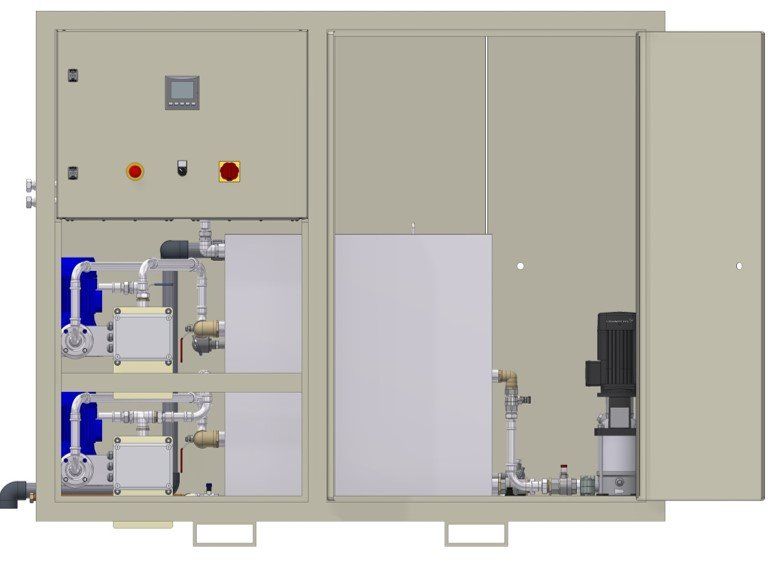

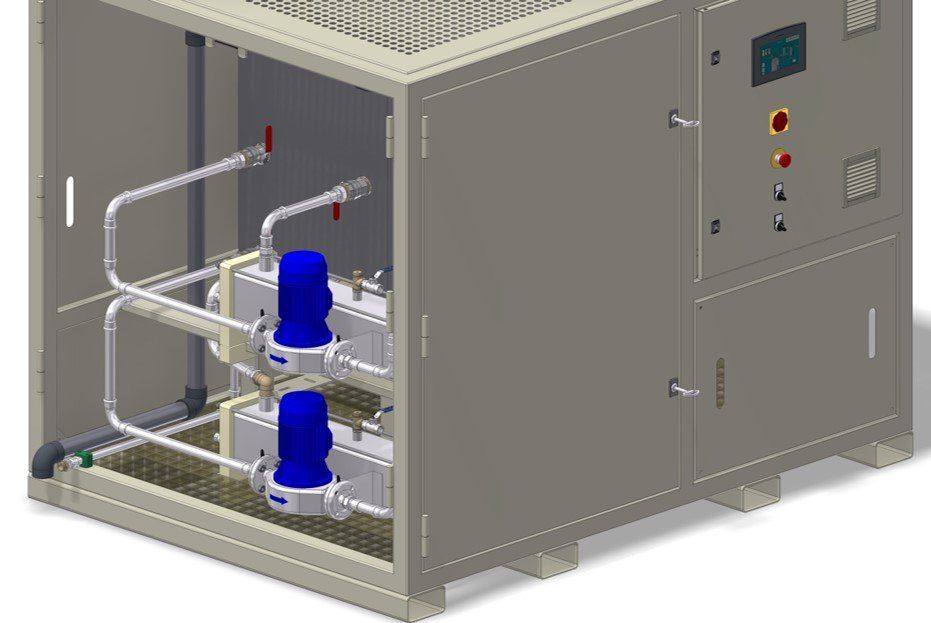

MSBA-2-300

Main Features

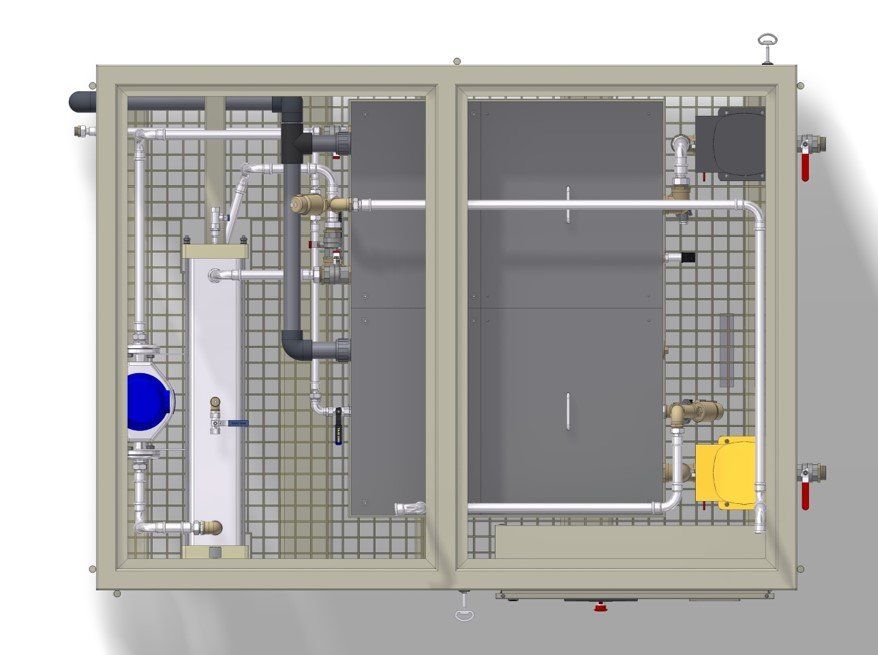

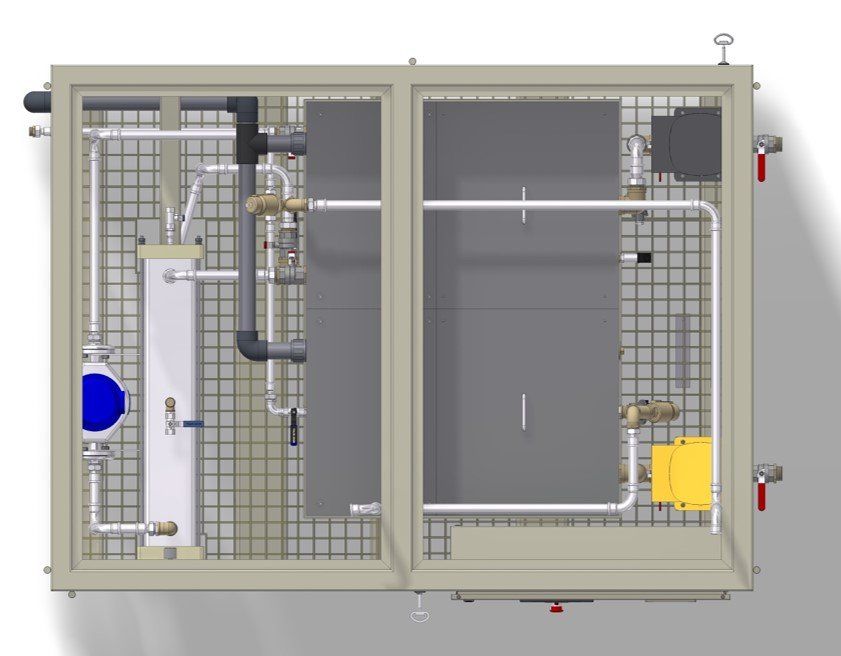

1. Stainless steel tank. Insulated cold water tank, 300L capacity.

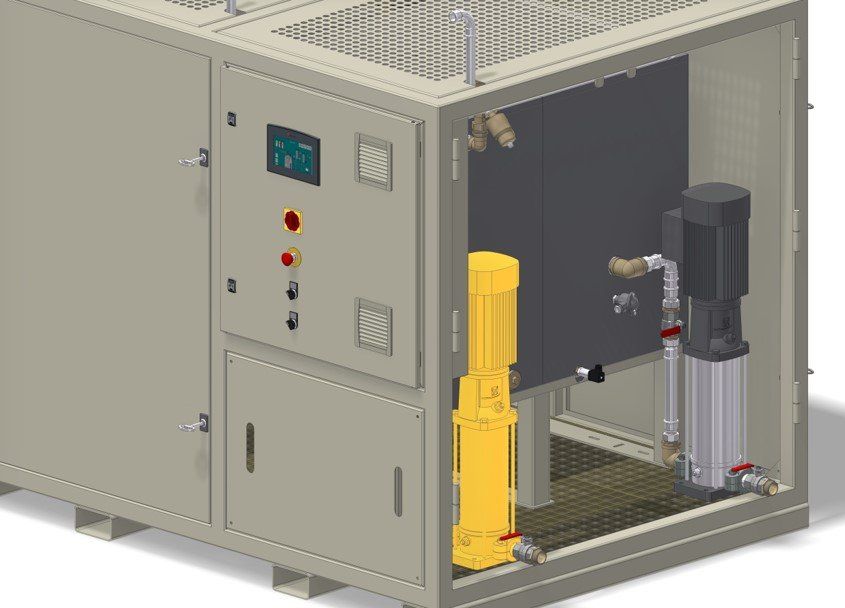

2. 1 X cold water supply pump with PID control 0.1 to 6 bar = 50 l/min

3. Stainless steel tank. Insulated hot water tank, 300L capacity.

4. 1 X hot water supply pump with PID control 0.1 to 6 bar = 50 l/min

5. Electric flow boiler with 1 27 KW system with recirculation system

6. Pump control software integrated into current bench

Currently, SEDAL's iSCU CPU test bench supplies recirculated cold water at room temperature.

These conditions do not allow some functional tests to be carried out with hot water supply at T>60ºC.

Application

Advantages

Requirements

General Technical Specifications

Hydraulic Connections

Command and Control

Integration into Test Bank

Display

Technical Installation Data

| Total Installation Width | 2.000 mm |

| Fund | 1.500 mm |

| Height | 1.600 mm |

| Net Weight without Water | 370 Kg (aprox.) |

| Weight with Water in Tanks | 970 Kg (aprox.) |

| Food Tank Capacity | 2 x 300 Liters |

| Strain | 380 V F N G 50/60 Hz |

| Power Pumps SBAD-2 | 2 x 1.5 kW = 3 kW |

| Boiler Power | 3 x 9 = 27 kW |

| Refrigerator Power | - |

| Total Installed Power | 30 kW |

| Cold Water Temperature | Environment |

| Hot Water Temperature | 70-75 ºC |